BEVERAGE INDUSTRY

Sonra Id’s products offer comprehensive support for beverage industry customers, addressing key challenges such as product identification, quality control, supply chain optimization, compliance management, and consumer engagement. With Sonra Id’s tailored solutions, businesses can gain a competitive edge and drive success in the dynamic beverage market.

Product Identification and Traceability: Sonra Id offers robust solutions for product identification and traceability in the beverage industry. By implementing Sonra ID systems, businesses can track their beverage products from manufacturing to distribution, ensuring accuracy in inventory management, batch tracking, and compliance with regulatory standards.

Quality Control and Assurance: Sonra Id’s solutions help beverage manufacturers maintain quality control and assurance throughout the production process. With features such as real-time monitoring and data analytics, businesses can identify and address any issues related to product quality, ensuring consistency and customer satisfaction.

Supply Chain Optimisation: Sonra Id’s products enable optimisation of the beverage supply chain by providing visibility and transparency at every stage. From raw material sourcing to delivery to end consumers, businesses can use Sonra Id’s solutions to streamline operations, minimize waste, and enhance overall efficiency.

Compliance Management: In the highly regulated beverage industry, compliance with safety and labelling standards is crucial. Sonra Id’s solutions include features for accurate labelling, allergen tracking, and compliance documentation, helping businesses meet regulatory requirements and avoid penalties or recalls.

Consumer Engagement: Sonra Id offers innovative solutions to enhance consumer engagement in the beverage industry. With features such as QR codes and RFID tags, businesses can provide consumers with access to product information, origin details, and sustainability initiatives, fostering trust and brand loyalty.

Overall, Sonra ID offers comprehensive support for beverage industry customers, addressing key challenges such as product identification, quality control, supply chain optimization, compliance management, and consumer engagement. With Sonra Id’s tailored solutions, businesses can gain a competitive edge and drive success in the dynamic beverage market.

How can we help your Beverage Business?

Barcode Systems

Barcodes are extensively used in the beverage industry for product identification, inventory management, and traceability. Barcodes can be printed on bottles, cans, or packaging to facilitate quick and accurate data capture throughout the supply chain

Do you have a question about how best to introduce or update your barcode systems? Talk to our team today for some professional advice.

RFID (Radio Frequency Identification)

RFID technology offers advanced tracking capabilities by using radio waves to identify and track beverage products and assets in real-time. RFID tags can be embedded in packaging or attached to containers, enabling automated inventory management, asset tracking, and anti-counterfeiting measures.

Do you have a specific question about RFID? Talk to our professionals today

QR CODES

QR codes provide a versatile solution for engaging consumers and conveying product information. Beverage companies often use QR codes on labels or packaging to provide access to nutritional information, promotional offers, and brand stories, enhancing consumer engagement and loyalty.

Batch and Lot Tracking Systems

Batch and lot tracking systems are essential for maintaining traceability and ensuring product quality and safety in the beverage industry. Auto ID solutions enable businesses to track batches of raw materials, ingredients, and finished products throughout the manufacturing process, facilitating recall management and compliance with regulatory requirements.

Tamper-Evident Labels

Tamper-evident labels equipped with Auto ID features such as barcodes or RFID tags help prevent product tampering and ensure the integrity of beverage products. These labels provide visible evidence of tampering, enhancing consumer trust and product safety.

Temperate Monitoring Systems

Temperature monitoring is critical for preserving the quality and safety of beverages, particularly perishable products. Auto ID solutions equipped with temperature sensors and data loggers enable businesses to monitor and record temperature conditions during storage, transportation, and distribution, ensuring compliance with food safety regulations.e or contamination incidents.

Sonra ID Solutions play a vital role in enhancing visibility, traceability, and safety in the beverage industry, enabling businesses to streamline operations, improve efficiency, and maintain compliance with regulatory requirements.

TITLE HERE WITH A PRODUCT EXAMPLE FOR THE BEVERAGE INDUSTRY

Popular in the BEVERAGE industry

BROWSE MORE

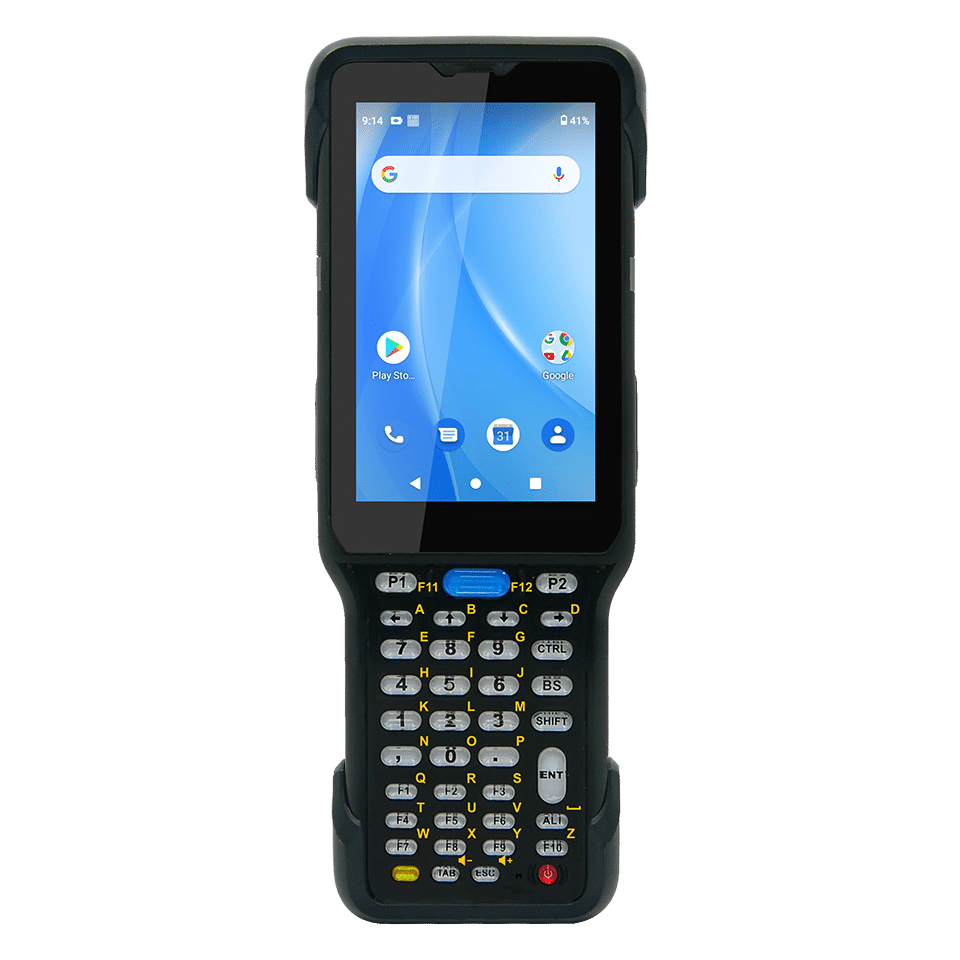

Unitech HT730 Rugged Handheld Terminal

The Unitech HT730 is an ergonomic one-hand operation handheld terminal with keypad and powerful data collection solutions. Offering Android 10 OS with GMS certification, the HT730 is equipped with Qualcomm® Artificial Intelligence (AI) CPU to deliver users excellent performance for smarter, more intuitive interactions which is suitable to improve your work efficiency in a wide range of applications in warehousing, logistics, and field service.

Features

- Android 10 OS with GMS certified

- Ergonomic one-handed operation

- Superior 2D scanning performance: Support 30-degree scanning tilt down

- Superior performance with the scanning range up to 20m away

- Support IEEE 802.11a/b/g/n, 802.11ax-ready, 802.11ac Wave 2 with 2X2 MU-MIMO Wi-Fi Standard

- 6700mAh battery for 20-26 hours operation

- True Hot-swap battery design without downtime

- 1.8M drop-resistant housing (2.4M with bumper)

- IP65/IP67 protection against water and dust

- Durable keypad with backlight: 38/29 keys with 2.5 million lifetime clicks

- Support Bluetooth® 5.1

- Support MDM software and utilities such as MoboLink, StageGo, Ivanti Wavelink and StayLinked

Specification

Operation System

OS: Android 10

GMS certified: GMS certified

CPU: Qcta-core 2.3 GHz, Qualcomm 720G (SM7125)

AI: 5th Gen Qualcomm AI Engine

Memory: RAM 4GB

Flash 64GB

Languages support: Multi-languages

Display

Screen Size: 4”TFT-LCD WVGA (480×800) colour screen (400 nits)

Touch Panel: Ultra-sensitive capacitive touch screen, compatible with gloves and support wet resistance

Buttons / Keypad

Buttons / Keypad: Numeric (29 key)/ Function Numeric (38 key) with backlight

Camera

Camera: Rear 13 MP Autofocus with flash

Indicator Type

Type: LED, Speaker, Vibrator

Symbologies

1D Barcodes: 1D : UPC/EAN/JAN, GS1 DataBar, Code 39, Code

128, Code 32, Code 93, Codabar/NW7, Interleaved 2

of 5, Matrix 2 of 5, MSI, Trioptic,

2D Barcodes: 2D : PDF417, MicroPDF417, GS1 Composite ,

Code11, Aztec Code, Data Matrix, QR Code, Micro

QR Code, MaxiCode, Han Xin Code, DOT Code

Postal: Intelligent Mail Barcode, Postal-4i, Australian

Post, Japanese Post, Netherlands (KIX) Post,

Postnet, Planet Code

RFID

UHF RFID: Frequency: 865~868MHz, 902~928MHz

Protocol: EPC global Class 1 Gen 2 ISO 18000-6C/6B

Antenna gain: 4dbi

Output Power : 1-30dbm adjustable

Data Capture Range: 6~8 meters

HF RFID: Support HF/NFC

Frequency 13.56Mhz

Support: ISO14443A/B, ISO15693 standard

I/O Interfaces

USB: USB 3.1 (type-C) support USB OTG

Support Display Port Mode

Ethernet/USB-Host via cradle

OTG: Yes, over USB Type-C

POGO PIN: Custom IO connector (include USB Host)

SIM Slot: Nano SIM Slot x 2

Expansion Slot: Micro SD/TF x 1(Support SD, SDHC and SDXC) up to 256GB

Audio: 2W output, One speaker with Smart PA (105 dB at 10cm),

Dual-Microphone, support noise cancellation

Power Source

Main battery: Main battery 3.7V 6700mAh

Hot Swap: Keeps applications active up to 1 minute

Communication

Bluetooth®: Bluetooth 5.1

WLAN: IEEE 802.11a/b/g/n/d/h/i/k/r/v/ac/ax ready (8ss and TWT), 802.11ac Wave 2

(Dual Antenna, 2X2 MU-MIMO support)

WWAN: LTE Advanced Support Up to CAT4

LTE (FDD) – Bands 1, 2, 3, 4, 5, 7, 8, 17, 20, 28

LTE (TDD) – Bands 38, 39, 40, 41

UMTS/HSPA+ (3G) – Bands 1, 2, 5, 8

GSM/GPRS/EDGE Quad-Band (850/900/1800/1900 MHz)

GPS: GPS, GLONASS, Galileo, BeiDou

Sensors: Gyroscope, G-sensor, E-compass, Light & Proximity Sensor

Software

MDM Software: SOTI, AirWatch, 42Gears, Ivanti Wavelink, and MoboLink

Enclosure

Dimensions ( W x H x D ): 195 mm x 72 mm x 34 mm

Weight: 395g(with battery)

Durability

Drop Specification: 1.8m / 2.4m(with Bumper)

Sealing: IP65 / IP67

Tumble test: Tumble 600 times (1.6 ft./0.5 m)

Environmental

Operating temperature: -20°C to +50°C

Storage temperature: – 30°C to 70°C (without battery)

Charging temperature: 0°C to 45°C

Relative Humidity: 5% ~ 95% (non-condensing)

Regulatory Approvals

Regulatory Approvals: CE, FCC, NCC, IC, VCCI, TELEC, CCC, SRRC, RoHS, CEC, BQB, GMS, N-Mark

Warranty

Hardware Warranty: 12 months

Statement: This product is warranted against defects in workmanship and materials for a period of twelve months from the date of shipment. Accessories are warranted for three months to one year. Our different regions have varying warranty terms, and offer extended and comprehensive warranties, so please contact your local representative for more information.

Industries and Applications

Airline / Manufacturing / Logistics

✔ The Airline Ground Services|Read ID numbers from passports

✔ Manufacturing|Read vehicle registration numbers and electronic chips

✔ Logistics&Retail|Read lot numbers printed on the package

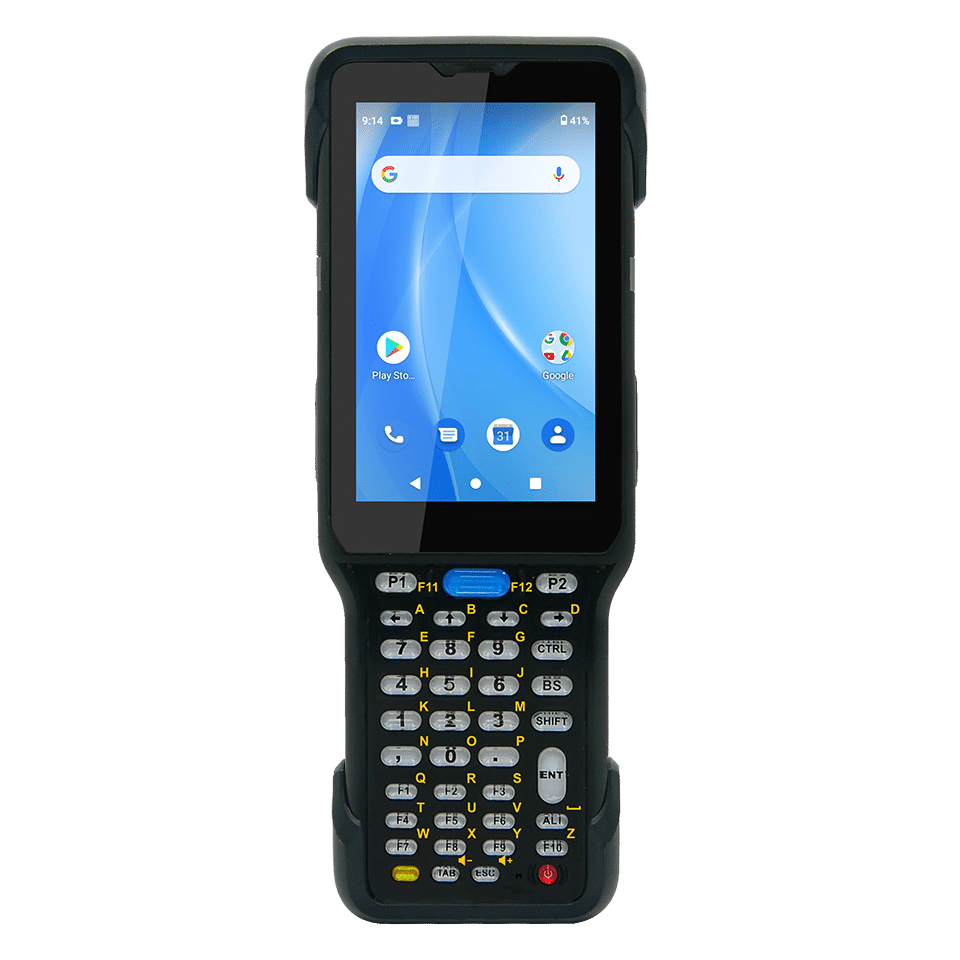

Unitech HT730 Rugged Handheld Terminal

The Unitech HT730 is an ergonomic one-hand operation handheld terminal with keypad and powerful data collection solutions. Offering Android 10 OS with GMS certification, the HT730 is equipped with Qualcomm® Artificial Intelligence (AI) CPU to deliver users excellent performance for smarter, more intuitive interactions which is suitable to improve your work efficiency in a wide range of applications in warehousing, logistics, and field service.

Features

- Android 10 OS with GMS certified

- Ergonomic one-handed operation

- Superior 2D scanning performance: Support 30-degree scanning tilt down

- Superior performance with the scanning range up to 20m away

- Support IEEE 802.11a/b/g/n, 802.11ax-ready, 802.11ac Wave 2 with 2X2 MU-MIMO Wi-Fi Standard

- 6700mAh battery for 20-26 hours operation

- True Hot-swap battery design without downtime

- 1.8M drop-resistant housing (2.4M with bumper)

- IP65/IP67 protection against water and dust

- Durable keypad with backlight: 38/29 keys with 2.5 million lifetime clicks

- Support Bluetooth® 5.1

- Support MDM software and utilities such as MoboLink, StageGo, Ivanti Wavelink and StayLinked

Specification

Operation System

OS: Android 10

GMS certified: GMS certified

CPU: Qcta-core 2.3 GHz, Qualcomm 720G (SM7125)

AI: 5th Gen Qualcomm AI Engine

Memory: RAM 4GB

Flash 64GB

Languages support: Multi-languages

Display

Screen Size: 4”TFT-LCD WVGA (480×800) colour screen (400 nits)

Touch Panel: Ultra-sensitive capacitive touch screen, compatible with gloves and support wet resistance

Buttons / Keypad

Buttons / Keypad: Numeric (29 key)/ Function Numeric (38 key) with backlight

Camera

Camera: Rear 13 MP Autofocus with flash

Indicator Type

Type: LED, Speaker, Vibrator

Symbologies

1D Barcodes: 1D : UPC/EAN/JAN, GS1 DataBar, Code 39, Code

128, Code 32, Code 93, Codabar/NW7, Interleaved 2

of 5, Matrix 2 of 5, MSI, Trioptic,

2D Barcodes: 2D : PDF417, MicroPDF417, GS1 Composite ,

Code11, Aztec Code, Data Matrix, QR Code, Micro

QR Code, MaxiCode, Han Xin Code, DOT Code

Postal: Intelligent Mail Barcode, Postal-4i, Australian

Post, Japanese Post, Netherlands (KIX) Post,

Postnet, Planet Code

RFID

UHF RFID: Frequency: 865~868MHz, 902~928MHz

Protocol: EPC global Class 1 Gen 2 ISO 18000-6C/6B

Antenna gain: 4dbi

Output Power : 1-30dbm adjustable

Data Capture Range: 6~8 meters

HF RFID: Support HF/NFC

Frequency 13.56Mhz

Support: ISO14443A/B, ISO15693 standard

I/O Interfaces

USB: USB 3.1 (type-C) support USB OTG

Support Display Port Mode

Ethernet/USB-Host via cradle

OTG: Yes, over USB Type-C

POGO PIN: Custom IO connector (include USB Host)

SIM Slot: Nano SIM Slot x 2

Expansion Slot: Micro SD/TF x 1(Support SD, SDHC and SDXC) up to 256GB

Audio: 2W output, One speaker with Smart PA (105 dB at 10cm),

Dual-Microphone, support noise cancellation

Power Source

Main battery: Main battery 3.7V 6700mAh

Hot Swap: Keeps applications active up to 1 minute

Communication

Bluetooth®: Bluetooth 5.1

WLAN: IEEE 802.11a/b/g/n/d/h/i/k/r/v/ac/ax ready (8ss and TWT), 802.11ac Wave 2

(Dual Antenna, 2X2 MU-MIMO support)

WWAN: LTE Advanced Support Up to CAT4

LTE (FDD) – Bands 1, 2, 3, 4, 5, 7, 8, 17, 20, 28

LTE (TDD) – Bands 38, 39, 40, 41

UMTS/HSPA+ (3G) – Bands 1, 2, 5, 8

GSM/GPRS/EDGE Quad-Band (850/900/1800/1900 MHz)

GPS: GPS, GLONASS, Galileo, BeiDou

Sensors: Gyroscope, G-sensor, E-compass, Light & Proximity Sensor

Software

MDM Software: SOTI, AirWatch, 42Gears, Ivanti Wavelink, and MoboLink

Enclosure

Dimensions ( W x H x D ): 195 mm x 72 mm x 34 mm

Weight: 395g(with battery)

Durability

Drop Specification: 1.8m / 2.4m(with Bumper)

Sealing: IP65 / IP67

Tumble test: Tumble 600 times (1.6 ft./0.5 m)

Environmental

Operating temperature: -20°C to +50°C

Storage temperature: – 30°C to 70°C (without battery)

Charging temperature: 0°C to 45°C

Relative Humidity: 5% ~ 95% (non-condensing)

Regulatory Approvals

Regulatory Approvals: CE, FCC, NCC, IC, VCCI, TELEC, CCC, SRRC, RoHS, CEC, BQB, GMS, N-Mark

Warranty

Hardware Warranty: 12 months

Statement: This product is warranted against defects in workmanship and materials for a period of twelve months from the date of shipment. Accessories are warranted for three months to one year. Our different regions have varying warranty terms, and offer extended and comprehensive warranties, so please contact your local representative for more information.

Industries and Applications

Airline / Manufacturing / Logistics

✔ The Airline Ground Services|Read ID numbers from passports

✔ Manufacturing|Read vehicle registration numbers and electronic chips

✔ Logistics&Retail|Read lot numbers printed on the package