Product Coding and Marking

Rea Jet Coding and Marking Systems

Some questions to consider..

- Product surface to be marked or coded?

- Are barcodes required?

- Environment for marking to take place?

- Monochrome or Colour?

- Connectivity options?

- Support and Service options?

- Environment of product usage?

- Ease of operator use?

- Ease of operator maintenance?

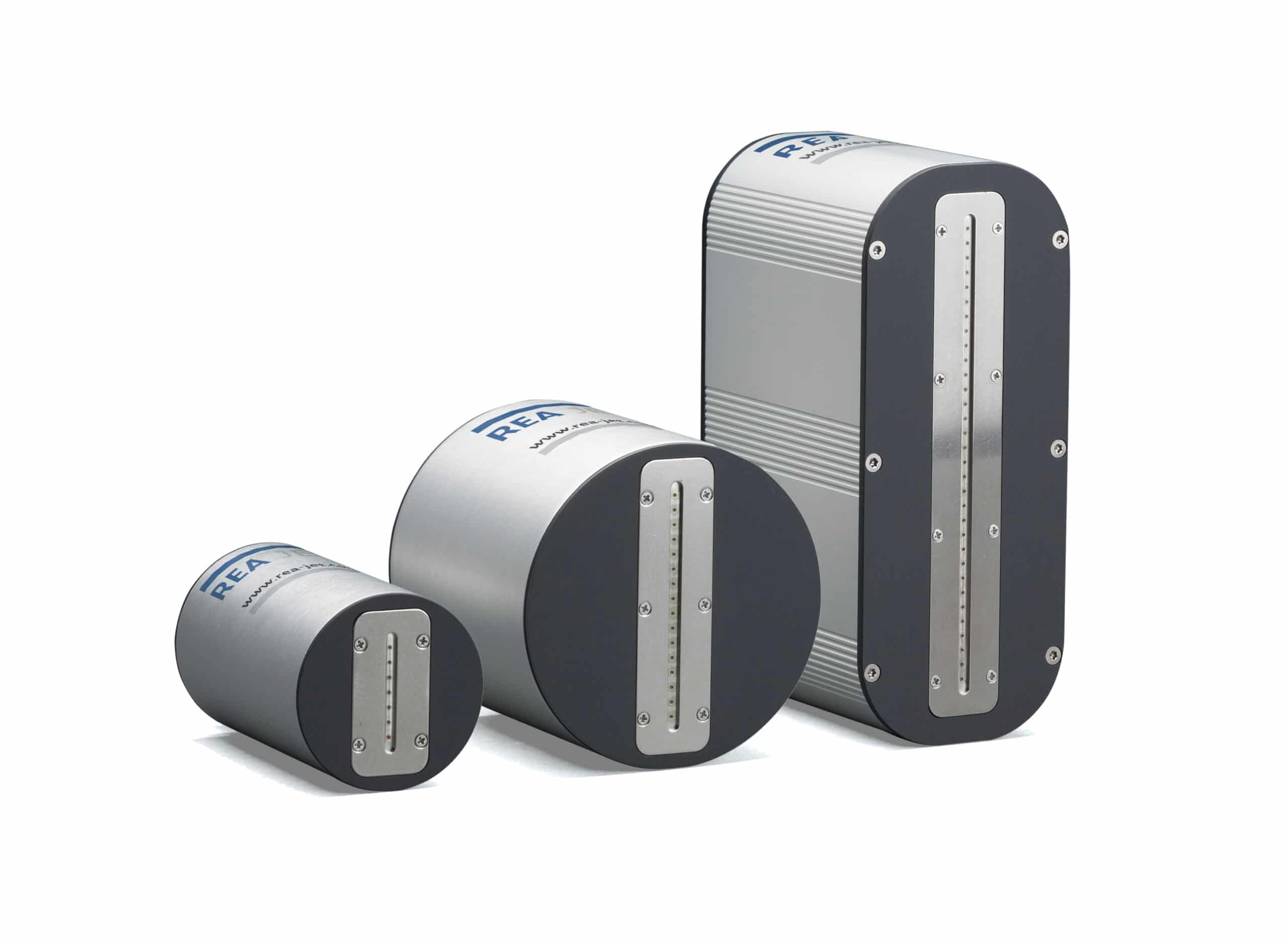

The REA JET Large Character Inkjet Printer is a robust, modular coding and marking system for the harsh industrial environment. Texts, data or logos can be printed up to a print height of 140 mm per print head or several can be combined for large print images. With the new generation of the large character inkjet printer DOD 2.0 we have further improved our printing systems.

Marking in hi-res can be achieved with our High Resolution Inkjet Printers. The innovative, maintenance-free REA JET HR coding and marking system with HP cartridge technology enables print of up to 12.7 mm per print head. Intuitive operation and advanced print head design ensure that this coding and marking system is fully suitable for industrial applications. The next generation of REA JET GK 2.0 high resolution coding and marking systems, based on piezo technology, is suitable for a wide range of applications including coding and marking on absorbent and porous surfaces with a print height of up to 100 mm.

The Small Character Inkjet Printer based on continuous inkjet technology prints texts, dates, codes and logos in good resolution at high speed. With the new generation of the SC 2.0 small character inkjet printer, a coding and marking system has been developed that can print up to 8 lines of text at a resolution of 48 pixels.

Our REA JET Laser Systems offer marking systems for permanent and tamper-proof marking. Due to the captive nature of the marking, the use of laser systems is ideal for tracing products and for counterfeit protection. The CO2 laser is particularly suitable for marking glass, rubber and organic surfaces. Whereas the fiber laser is used for metals and plastics.